Plastic Industry

Ecochillers on the Plastic Industry

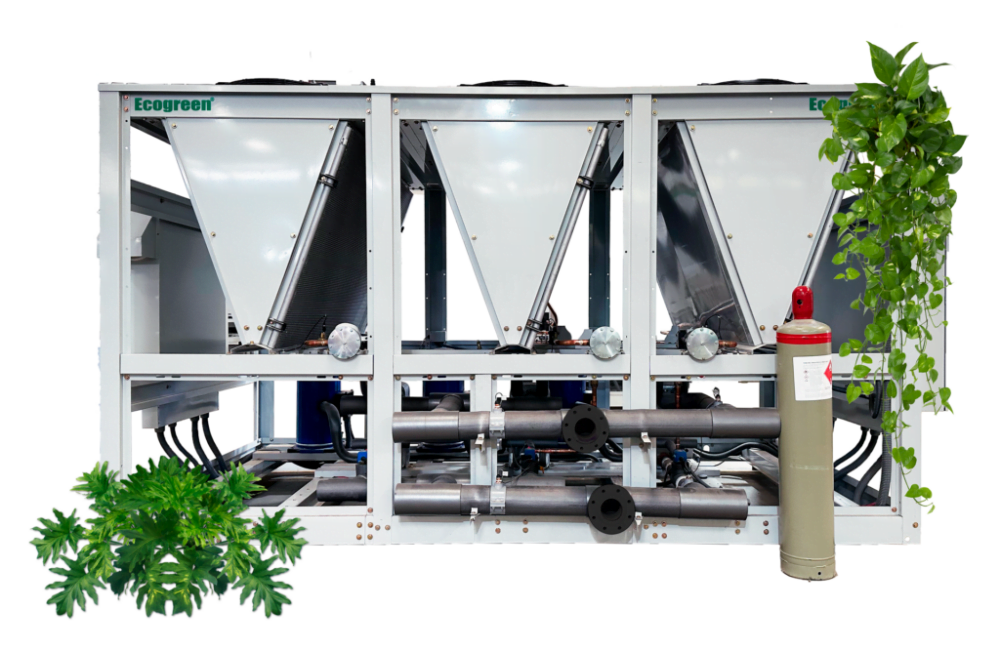

Ecochillers® has proven experience in the plastics industry, ensuring the most efficient designs. Our chillers are installed to cooling plastic that is injected, extruded or blown. The equipment used to create a plastic mold may also require cooling allowing the machine to operate more efficiently.

This will assist the machine in operating more efficiently and aid in the extension of the life of the machine.

Contact us if you need help selecting a chiller based on your requirements to plastic cooling, mold cooling, injection molding chillers, process cooling equipment, plastic injection molding etc.

What is chiller plastic?

A plastics chiller is a refrigerated unit that cool water to cools plastics Molding, extruders, Blowing throughout the manufacturing process. a closed-loop system is recomended, so no debris from the plastic can mix with your process water.

Contact us today!

- Determine Plastic material weight per hour.

- Determine cooling capacity on Table 1, based on Cooling Mold Only and by separate Oil Cooling Press Pump.

- Determine if the extruder or any auxiliary equipment will require chill water.

- Size the equipment cooling capacity based on Table 1, Column 2 Mold Cooling and Column 3 Oil Cooling.

- if you desire to use the same Chiller for Mold and Oil Cooling Combine the process and equipment cooling requirements, Not Recomended, Ecochillers Recomends a Chiller for Mold Coolig and a Closed Circuit Dry Cooler or Adiabtic and Evaporative Coolrer, (also you can Go for a Cooling Tower but more Energy and Water waste may occour.

- Size your chiller by the Total Nominal Chiller Capacity, keep in mind some other loads as Heat gaining for not Insulated Parts and Piping.

- Select the real chiller capacity made the corrections based on ambient temperaures, enviroment a well ventilated Chiller area, see Ecochillers Chiller Instalation recomendations Manual.

Plastics Global Impact Report 2023

The subsequent report showcases the achievements of the Operation Clean Sweep® (OCS) Programs in 2023. OCS, initiated by the Plastics Industry Association (PLASTICS) in 1991 and administered in collaboration with ACC’s Plastics Division since 2004, aims to eliminate resin loss in operations. It has expanded internationally since 2010, involving over two dozen association partners, 65 countries, and 4,000 participating companies worldwide.

Currently, there are over 22 active OCS Programs across 6 continents, each tailored to its geographic and cultural context while adhering to the core OCS Pledge. The recently published Guide to International OCS Programs offers insights into individual program requirements and eligibility. Meanwhile, the OCS Annual Impact Report highlights achievements attained by each program throughout the year, such as membership growth, enhanced program rigor through data reporting or external inspections, and notable success stories.

Additionally, our Chillers and Heat Pumps can contribute to reducing environmental impact by utilizing eco-friendly refrigerants with low GWP and incorporating heat recovery technology, resulting in up to 70% energy savings.

Addressing Environmental Impact in Plastic Manufacturing

Eco-Friendly Cooling Solutions

Plastic manufacturing is a vital industry with widespread applications across various sectors. However, its environmental impact cannot be overlooked. From raw material extraction to end-of-life disposal, plastic production contributes significantly to pollution, resource depletion, and climate change.

One of the primary concerns is the energy-intensive nature of plastic manufacturing processes. Traditional cooling systems, such as air conditioning and refrigeration units, often rely on refrigerants with high Global Warming Potential (GWP), contributing to greenhouse gas emissions. Additionally, the excessive energy consumption of these systems further exacerbates environmental strain.

To mitigate these challenges, innovative solutions are essential. Chillers and Heat Pumps offer a sustainable alternative for cooling applications in plastic manufacturing facilities. These systems utilize eco-friendly refrigerants with low GWP, minimizing their environmental footprint. Furthermore, they incorporate heat recovery technology, allowing them to capture waste heat generated during the cooling process and repurpose it for heating purposes. This not only reduces energy consumption but also enhances overall efficiency, leading to significant energy savings of up to 70%.

By implementing Chillers and Heat Pumps in plastic manufacturing operations, companies can take proactive steps towards reducing their environmental impact. These eco-friendly cooling solutions not only contribute to lowering greenhouse gas emissions but also promote energy efficiency and sustainability in the industry. As the demand for sustainable practices continues to grow, adopting such technologies becomes imperative for fostering a greener future.

In conclusion, the adoption of Chillers and Heat Pumps with eco-friendly refrigerants and heat recovery capabilities presents a promising opportunity for mitigating the environmental impact of plastic manufacturing. By embracing sustainable cooling solutions, manufacturers can align their operations with environmental goals while achieving cost savings and operational efficiency.

What size chiller is needed for a polypropylene molding operation ?

Consult our Plastic Processing Sizing data table.

INJECTION OR BLOW MOLD COOLING CAPACITY BASED ON PRODUCTION IN KG/H |

|||

|---|---|---|---|

| KG / H | KCAL / H FRIG / H | KBTU / H | COOLING TONS |

| 5 | 1,250 | 4.958 | 0.5 |

| 10 | 2,500 | 9.915 | 0.9 |

| 15 | 3,750 | 14.872 | 1.3 |

| 20 | 5,000 | 19.829 | 1.7 |

| 25 | 6,250 | 24.786 | 2.1 |

| 30 | 7,500 | 29.743 | 2.5 |

| 35 | 8,750 | 34.700 | 2.9 |

| 40 | 10,000 | 39.657 | 3.4 |

| 45 | 11,250 | 44.614 | 3.8 |

| 50 | 12,500 | 49.571 | 4.2 |

| 55 | 13,750 | 54.528 | 4.6 |

| 60 | 15,000 | 59.486 | 5 |

| 65 | 16,250 | 64.443 | 5.4 |

| 70 | 17,500 | 69.400 | 5.8 |

| 75 | 18,750 | 74.357 | 6.2 |

| 80 | 20,000 | 79.314 | 6.7 |

| 85 | 21,250 | 84.271 | 7.1 |

| 90 | 22,500 | 89.228 | 7.5 |

| 95 | 23,750 | 94.185 | 7.9 |

| 100 | 25,000 | 99.142 | 8.3 |

| 105 | 26,250 | 104.099 | 8.7 |

| 110 | 27,500 | 109.056 | 9.1 |

| 115 | 28,750 | 114.013 | 9.6 |

| 120 | 30,000 | 118.971 | 10 |

| 125 | 31,250 | 123.928 | 10.4 |

| 130 | 32,500 | 128.885 | 10.8 |

| 135 | 33,750 | 133.842 | 11.2 |

| 140 | 35,000 | 138.799 | 11.6 |

| 145 | 36,250 | 143.756 | 12 |

| 150 | 37,500 | 148.713 | 12.4 |

| 155 | 38,750 | 153.670 | 12.9 |

COOLING TONS FOR PLASTIC EXTRUSION MACHINES |

|||

KG/H X 200 |

|||

3,024 |

|||

PER EACH MOLD ELECTRIC HEATER KW SUM THE COOLING CAPACITY REQUIRED |

|||

860.4 KCAL/H (0,28 TONS) |

|||

SYSTEM HYDRAULIC OIL COOLING CAPACITY |

||||

|---|---|---|---|---|

PUMP SIZE | ||||

| HP | KW / H | KCAL / H FRIG / H | KBTU / H | COOLING TONS |

| 5 | 3.8 | 3,208.1 | 12.723 | 1.1 |

| 10 | 7.5 | 6,416.2 | 25.445 | 2.2 |

| 15 | 11.2 | 9,624.3 | 38.167 | 3.2 |

| 20 | 15 | 12,832.4 | 50.889 | 4.3 |

| 25 | 18.7 | 16,040.4 | 63.611 | 5.4 |

| 30 | 22.4 | 19,248.5 | 76.334 | 6.4 |

| 35 | 26.1 | 22,456.6 | 89.056 | 7.5 |

| 40 | 29.9 | 25,664.7 | 101.778 | 8.5 |

| 45 | 33.6 | 28,872.8 | 114.500 | 9.6 |

| 50 | 37.3 | 32,080.8 | 127.222 | 10.7 |

| 60 | 44.8 | 38,497.0 | 152.667 | 12.8 |

| 75 | 56 | 48,121.2 | 190.833 | 16 |

| 100 | 74.6 | 64,161.6 | 254.444 | 21.3 |

| 150 | 111.9 | 96,242.4 | 381.666 | 31.9 |

| 200 | 149.2 | 128,323.2 | 508.887 | 42.5 |

| 225 | 167.8 | 144,363.6 | 572.498 | 47.8 |

| 250 | 186.5 | 160,403.9 | 636.109 | 53.1 |

| 275 | 205.1 | 176,444.3 | 699.720 | 58.4 |

| 300 | 223.8 | 192,484.7 | 763.331 | 63.7 |

| 350 | 261 | 224,565.5 | 890.552 | 74.3 |

| 400 | 298.3 | 256,646.3 | 1,017.774 | 84.9 |

| 500 | 372.9 | 320,807.8 | 1,272.217 | 106.1 |

| 550 | 410.2 | 352,888.6 | 1,399.439 | 116.7 |

| 600 | 447.5 | 384,969.4 | 1,526.661 | 127.3 |

| 650 | 484.8 | 417,050.2 | 1,653.882 | 137.9 |

| 700 | 522 | 449,130.9 | 1,781.104 | 148.5 |

| 750 | 559.3 | 481,211.7 | 1,908.326 | 159.1 |

| 800 | 596.6 | 513,292.5 | 2,035.547 | 169.7 |

| 850 | 633.9 | 545,373.3 | 2,162.769 | 180.3 |

| 900 | 671.2 | 577,454.1 | 2,289.991 | 190.9 |

| 1,000 | 745.7 | 641,615.6 | 2,544.434 | 212.1 |

| 1,341 | 1000 | 860,420.7 | 3,412.142 | 284.4 |

1 KW / H = 860.4 KCAL / H = 3.412 KBTU / H |

||||

1 TON REF = 3024 KCAL / H |

||||

| REFERENCE TEMPS.: | ||||

| AIR DB. TEMP.: | 77 ºF | 25 ºC | ||

| MOLD WATER TEMP.: | 53.6 ºF | 12 ºC | ||