SHOWROOM

We have been manufacturing and selling our Chillers all across the US, Canada, Latin America, the Caribbean, and even as far as Guam (US Navy), Hawaii, Saudi Arabia and Kenia since 1995, with only Premium Components, delivered from our Laredo, TX warehouse.

Our main market is based on custom made, special design, Industrial HVAC & Process, Scroll, Screw, Magnetic Centrifugal and Semi Hermetic Chillers from 1 and up to 250 tons, Modular up to 2,500 tons, (TUV listed), and we are about to be listed up to 600 tons.

Excellence and Expertise

Chillers and Air Conditioning Equipment Manufacturer and Dealers.

Custom solutions for industrial processes.

Based on Costumer needs, Ecochillers designs Chillers, Heat Pumps, Condensing Units, Dry Coolers, Adiabatic Coolers, Air Handler Units, Package Units, Skid Pumps, Water Receivors Tanks for HVAC and Process Including Components, Voltages, Dimensions Restrains, Vertical, Horizontal Configurations.

From 1 up to 375 ton tr (3.5 to 1312.5 kw ) on single Unit Water-cooled variable speed screw chiller will help you achieve superior efficiency in comfort cooling, heat pump, process cooling and thermal storage applications.

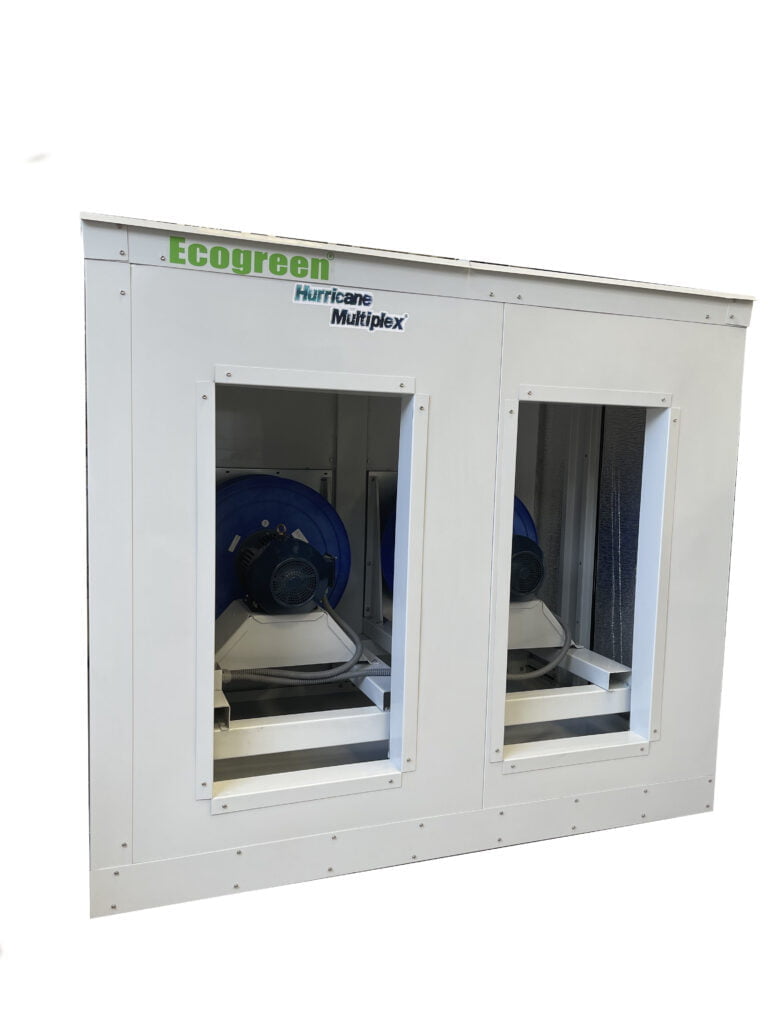

ECTAHUO

VIEW

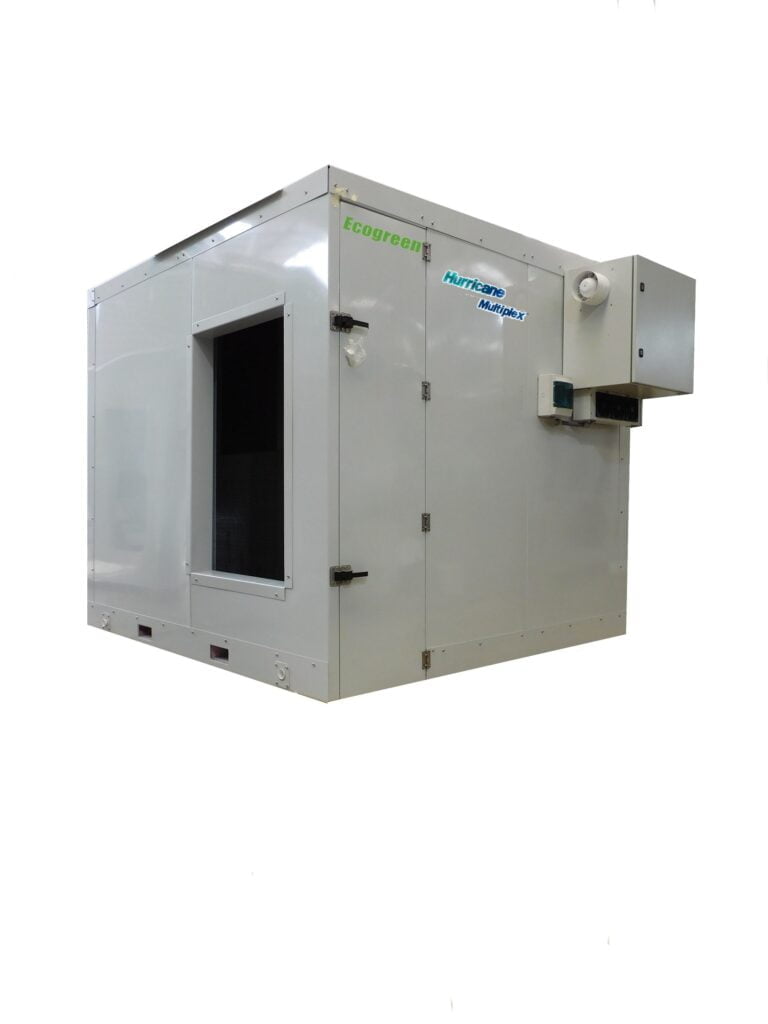

Features and Options*

- 5 to 250 ton

- Reduced operating costs

- Quiet operation

- Reduced installation expenses

- Reliable operation

- Plug-and-play hydronics

- Simple to specify

- Easy to start up and operate

- Heat Recovery Option

- Electric and Steam Heating Coil Optional

- EPA filters optional

- Indoor Design

- Outdoor Design

- Centrifugal Fans by Ziehl Abbeg

- EC Brushless Fan Motors option

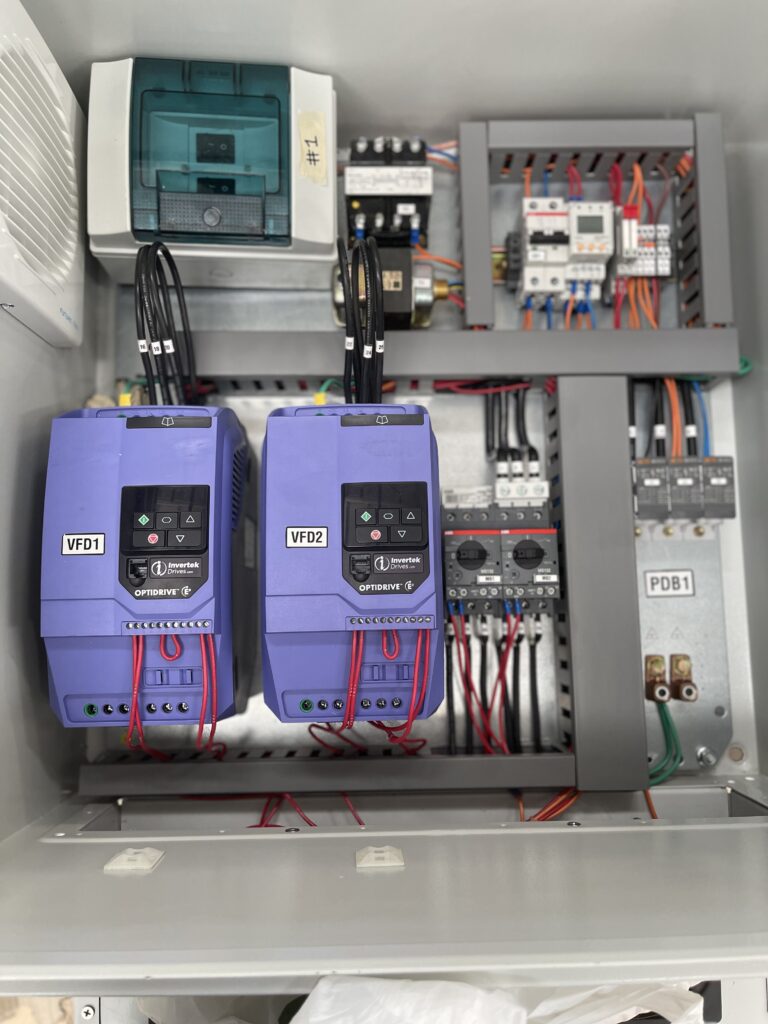

- VSD Control Technics, ABB, Nidec, Fuji, Teco

- Single and Double Wall Options

- Fire retardant

- Stainless Steel Walls All Option*

- Water Cooled Coils

- Direct Expansion options*

- Heat Pump Option*

Ecochillers designs are engineered with quality components and materials

System design services

Offered either on a consulting basis or as part of system purchase. These services include reviewing application, facility, environmental and budgetary considerations and working in concert with our client to design an optimal system.

Philosophy: Ecogreen is about respect and Protect the Enviroment providing solutions to reduce Energy Waste, increase Efficiency and NETZERO Goal .

Partnerships with other Big Players as JCI, Carrier, Guntner, Alfa LAval, Kelvion, Swep, Ziehl Abbeg, Rosenberg, Nidec, Carel, Fuji, Coilmaster, Evapco Alcoil, to achieve our Customers Success.

What is a Chiller?

A Chiller is a Machine that removes heat from one element (water/glycol/air) and deposits into another (ambient air or water). in Comfort or HAVC applications The standard design is a system that cools from 54°F water (water/glycol, or air) to 44° F cooling the water that drives the cooling capacity to different point or air handlers take the Room Heat and deposits the heat into the ambient air.

The function of controlling the temperature in manufacturing and process equipment can be achieved in four ways – 1) a cooling tower that supplies water at 85° F or higher and by using chillers that supply water at 55° F or lower.

A Portable Chiller – is a single pump chiller, can be supplied with either air or water cooled condensers, used to cool one or Several machines, process water flow standard 2.4 gpm/ton, this limits the use of this type of chiller.

A Process packaged Chiller – is a two pump system, one pump for the evaporator, the other for the process, can be supplied with either air cooled or water cooled condensers, no process water flow restrictions this type of chiller can be expandable as plant cooling load increases.

A Central Chilling System – is where one or more central chillers are connected to a common two pump tank set, stand-by pump (s), can be added, and chillers can be added to the maximum Process Cooling capacity, equal in pumps and water receivors.

Since 1987

Expertise:

Our Founder began in the HVAC and Refrigeration Market as a Service Engineer in a well knowed American Compressor Manufacturer, latter in 1993 start a small Contractor company as entrepreneur, working for York providing and Manufacturing Custom Water Cooled Condensing Units, Water cooled Amonia and Freon Screw Chillers, HVAC&R Complete Installations in Resorts, Piping Insulation for Wallmart and Nestle Distribution Centers, and in 2005 Ecochillers Corp. was founded continue on the Chillers and Condensing Units and other HVAC equipment Manufacture, in 2010 stablished Ecochillers Inc. in Austin TX. Involved in a wide range of Cooling and Heating applications such Heat Recovery Aplications for a Big American Chiller Manufacturer and lookig for International markets. We have the knowledge of what works and what questions to ask to ensure for a real optimal operation and integration systems.

What is an Adiabatic cooler?

An adiabatic cooler is a Closed Circuit Air Forced Cooled Coil (copper tubes and aluminum fins that conducts water, Oil or Glycol inside, its a Circuit Drycooler with Improve Efficiency thanks to the evaporative system) like a Car Radiator Cooler, that incorporates the benefit of water evaporation with Pre-cooling Pads, the Pads is a Cell surface with a small water falling film to humid the pads then Fans Ventilators Forced Ambient Air drive through the Pads, Water evaporates this evaporation take the heat from the air reducing the temperature of the Air and this Air goes trough the Coil or Radiator, the result is Colder Air Below the Ambient Temperature, this help the Cooler to be More Efficient and getting Lower Liquid Temperatures.

What is a Cooling Tower System?

A central Cooling Tower System – is where one or more cooling towers are connected to a common two pump tank set, standby pump (s), can be added, and towers can be added to the maximum cooling capacity of pump tank.

Cooling Towers has a limited low Temperatures according to climate conditions Relative Humidity, Ambient Air, Dew Point and altitude.

WATER COOLED CHILLERS

Offers the widest series of water-cooled chillers to meet your facility’s comfort cooling or process requirements, exceeding your efficiency expectations. A range from 1 to 600 tons (3.5-2100 kw), chillers offer the largest cooling capacity available on the market. Aside from centrifugal compressors, provides scrolls and screw units in addition to absorption chillers, Heat Recovery and Heat Pump design available.

Water Cooled Scroll VSD Chiller

1 to 350 tr (1,225 kw )

Water cooled scroll chillers provide chilled water for all air conditioning and Process applications that use central station air handling or terminal units, capable to go down to 22°F with glycol*

Air Cooled Scroll VSD Chiller

1 to 350 tr (1,225 kw )

Water cooled scroll chillers provide chilled water for all air conditioning and Process applications that use central station air handling or terminal units, capable to go down to 22°F with glycol*

Water Cooled Screw VSD Chiller

60 to 600 tr (210-21,000 kw )

Air-cooled variable speed screw chiller will help you achieve superior efficiency in comfort cooling, heat pump, process cooling and thermal storage applications, capable to go down to -40°F with glycol*

Air Cooled Screw VSD Chiller

60 to 600 tr (210-21,000 kw )

Air-cooled variable speed screw chiller will help you achieve superior efficiency in comfort cooling, heat pump, process cooling and thermal storage applications, capable to go down to -40°F with glycol*

Our Address

Ecochillers, Inc.

21 Waterway Avenue

Suite 300

The Woodlands, Texas 77380

Our Customers

The Ecochillers experience with excellent performance and low maintenance time.